The right power cable can make all the difference to an electrical project. Whether it's powering a home, a commercial building, or an industrial plant, the choice of power cable is crucial for safety, performance, and reliability.

As a leading supplier of top-quality power cables in the UK, we're here to guide you through the options available. In this blog, we'll break down the different types of power cables, their practical applications, and the distinct advantages they bring to your projects.

What are Power Cables?

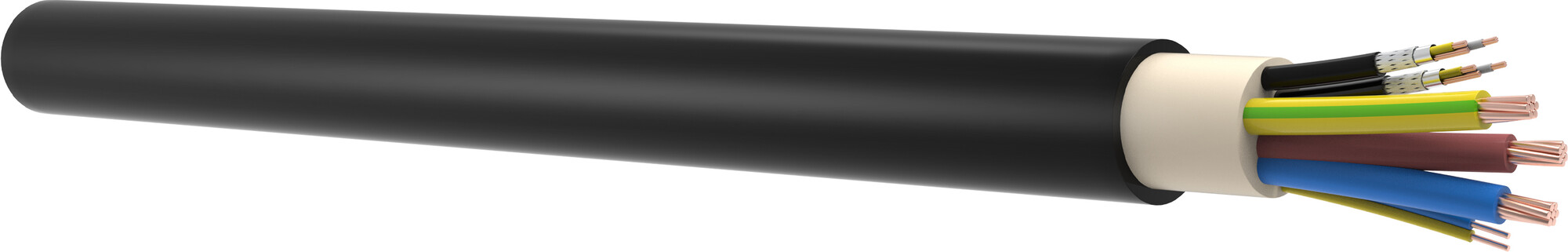

Power cables are insulated conductors used to transmit electrical energy efficiently and safely across various distances. They are essential for connecting electrical power sources to devices, machines, and systems. The importance of choosing the right cable lies in their ability to provide a secure and stable pathway, preventing power loss and ensuring safety.

Common Types of Power Cables

Low Voltage Power Cables

Low voltage power cables are designed for systems with voltages up to 1,000 volts. These cables are commonly used in residential and commercial settings for applications such as wiring homes, offices, and small businesses.

They are essential for connecting electrical outlets, lighting systems, and appliances to the main power supply. Their insulation provides protection against electrical shocks and short circuits, ensuring safe and reliable operation in everyday environments.

Medium Voltage Power Cables

Medium voltage power cables are used for systems with voltages ranging from 1,000 volts to 35,000 volts. These cables are typically found in industrial and urban infrastructure applications, such as powering factories, industrial plants, and public utilities.

They are designed to withstand higher electrical loads and harsh environmental conditions, providing a stable and efficient power supply to critical systems and infrastructure.

High Voltage Power Cables

High voltage power cables are designed for transmitting electrical power at voltages above 35,000 volts. These cables are crucial for power transmission and distribution networks, connecting power plants to substations and distributing electricity across vast distances.

High voltage cables are built to handle extremely high electrical loads and are engineered to minimise energy loss and withstand environmental stressors, ensuring the efficient delivery of electricity over long distances.

Specialised Power Cables

Armoured Power Cables

Armoured power cables are designed with a protective metal sheath that shields the internal conductors from mechanical damage. This robust construction provides excellent resistance to physical impacts, making them ideal for harsh environments.

The metal armour also offers enhanced protection against environmental factors such as moisture, chemicals, and extreme temperatures, ensuring long-term durability and reliability.

Armoured power cables are commonly used in underground installations, where they are buried directly in the ground or placed in ducts. They are also suitable for use in industrial settings, construction sites, and other environments where the cables may be exposed to physical stress and potential damage.

Flexible Power Cables

Flexible power cables are designed with highly pliable conductors and insulation materials, allowing them to bend and flex without breaking. This flexibility makes them ideal for applications where the cables need to move or be routed through tight spaces. These cables are also lightweight and easy to handle, simplifying installation and maintenance.

Flexible power cables are widely used in portable devices, movable machinery, and temporary power setups. They are essential in environments such as construction sites, events, and mobile units, where equipment needs to be frequently relocated or adjusted.

Submersible Power Cables

Submersible power cables are specifically engineered to operate in wet and underwater environments. They feature waterproof insulation and robust sheathing to prevent water ingress and protect the internal conductors. These cables are also designed to resist corrosion and other forms of degradation caused by prolonged exposure to water.

Submersible power cables are used in a variety of applications, including underwater lighting, fountain pumps, marine equipment, and sewage treatment plants. Their ability to function reliably in wet conditions makes them indispensable for maintaining electrical connectivity in aquatic environments.

Choosing the Right Power Cable for the Job

Assessing Voltage and Current Requirements

Determine the voltage and current levels needed for your application. Selecting a cable that can handle the required electrical load is critical for safety and performance.

Evaluating Environmental Conditions

Consider the environment in which the cable will be used. Factors such as temperature, moisture, chemical exposure, and physical stress will influence the choice of cable materials and construction.

Considering Cable Flexibility and Durability

Depending on the application, you may need a cable that offers flexibility for easy routing or enhanced durability for harsh conditions. Choose a cable that meets the specific demands of your environment.

Power Cable Size and Specifications

The size of a power cable, typically measured in square millimetres (mm²) of the conductor cross-section, determines its current-carrying capacity. Selecting the correct size ensures the cable can safely transmit the required electrical load without overheating.

Key Specifications to Look For When Choosing a Power Cable:

Conductor Material: Copper or aluminium, affecting conductivity and flexibility.

Insulation Type: Depending on the environmental and electrical requirements.

Shielding: Necessary for applications with high electromagnetic interference.

Temperature Rating: Ensures the cable can operate safely within the expected temperature range.

Applications of Different Types of Power Cables

Residential Applications

In residential settings, common power cables include low voltage cables for general wiring, flexible cables for appliances, and armoured cables for outdoor installations.

Commercial Applications

Commercial buildings often use medium voltage cables for distribution, flexible cables for office equipment, and insulated cables for lighting and HVAC systems.

Industrial Applications

Industrial environments require robust cables such as armoured cables for machinery, medium voltage cables for distribution, and submersible cables for wet areas. Industrial power cables must withstand harsh conditions, provide high performance, and ensure the safety and reliability of critical operations.

Power Cable FAQs

What are the different types of power cables?

Power cables are categorised into low voltage, medium voltage, and high voltage cables. Specialised types include armoured cables, flexible cables, and submersible cables, each designed for specific applications and environments.

How do I choose the right power cable for my needs?

Consider the voltage and current requirements, environmental conditions, flexibility, and durability needed for your application. Consulting with a professional or using a specification guide can help ensure you select the appropriate cable.

What are the types of power cable ends?

Power cable ends include plugs, sockets, and connectors. Common types are IEC, NEMA, and CEE connectors, each designed for specific regional standards and applications.

What factors should I consider when selecting a power supply cable?

Evaluate the electrical load, environmental conditions, insulation type, conductor material, and any specific requirements for flexibility or shielding to ensure the cable meets your needs.

How does the size of a power cable affect its performance?

The size of a power cable, determined by its conductor cross-section, affects its current-carrying capacity and resistance. Proper sizing ensures the cable can handle the electrical load without overheating and maintains efficiency.

What are the applications of high voltage power cables?

High voltage power cables are used in power transmission and distribution networks, connecting power plants to substations and distributing electricity over long distances with minimal energy loss.

Can power cables be used in underwater environments?

Yes, submersible power cables are specifically designed for underwater and wet environments. They feature waterproof insulation and robust sheathing to prevent water ingress and ensure reliable performance.

Alarm Cable

Arctic Grade Cable

Armoured Cable

Audio & Speaker Cable

Auto Cable

Bare Copper

Belden Equivalent Cable

Co-axial Cable

Data Cable

DC Telecom Cable

Defence Standard Cable

Emergency Lighting & Fire Detection Cable

EV Cable

Festoon

![Loose Tube Fibre Cross Section]()

Fixed Wiring PVC & LSOH Cable

Flatform

Flexible Control Cable

Flexible PVC Cable

Flexible Rubber Cable

General Wiring Cable PVC & LSOH

High Temperature Cable

High Voltage Cable

![5308 p1 t2 cat Cross Section]()

LSOH Flexible Cable

Medium Voltage Cable

NYY & N2XH Cable

Protected Wiring Cable

Silicone Cable

Solar Cable

Split Concentric Cable

Spiral Cable

Temporary Power Cable

Tri-Rated Cable

Welding Cable

Alarm Cable

Arctic Grade Cable

Armoured Cable

Audio & Speaker Cable

Auto Cable

Bare Copper

Belden Equivalent Cable

Co-axial Cable

Data Cable

DC Telecom Cable

Defence Standard Cable

Emergency Lighting & Fire Detection Cable

EV Cable

Festoon

![Loose Tube Fibre Cross Section]()

Fixed Wiring PVC & LSOH Cable

Flatform

Flexible Control Cable

Flexible PVC Cable

Flexible Rubber Cable

General Wiring Cable PVC & LSOH

High Temperature Cable

High Voltage Cable

![5308 p1 t2 cat Cross Section]()

LSOH Flexible Cable

Medium Voltage Cable

NYY & N2XH Cable

PAS - BS5308 Instrumentation Cable

Protected Wiring Cable

RS-232 Cable

RS-485 Cable

Silicone Cable

Solar Cable

Split Concentric Cable

Spiral Cable

Telephone Cable

Traffic Signal Cables

Temporary Power Cable

Tri-Rated Cable

Welding Cable

Airports

Automation & Process Control

![Automotive]()

Building & Construction

Communication & Telecommunication

Data Centres

Defence

![DNO 1]()

E-Mobility

Food & Beverage

Marine & Offshore

Mining, Drilling & Tunnelling

OEMs

Oil, Gas & Petrochemical

Rail & Metro

Renewable Energy

Switchgear

Power

Water Treatment